Bimanual Robot Smart Gripper

Outcome:

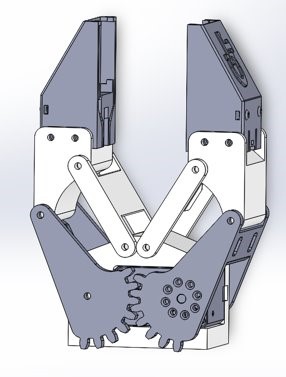

Within the subfield of agile legged locomotion and manipulation, I led a team of undergraduate students in designing/fabricating a 3-degree-of-freedom attachable mechanical gripper for the bipedal Digit robot using Gelsight sensors. This research project was executed within Dr. Ye Zhao's LAB-IDAR group at Georgia Tech.

Motivation:

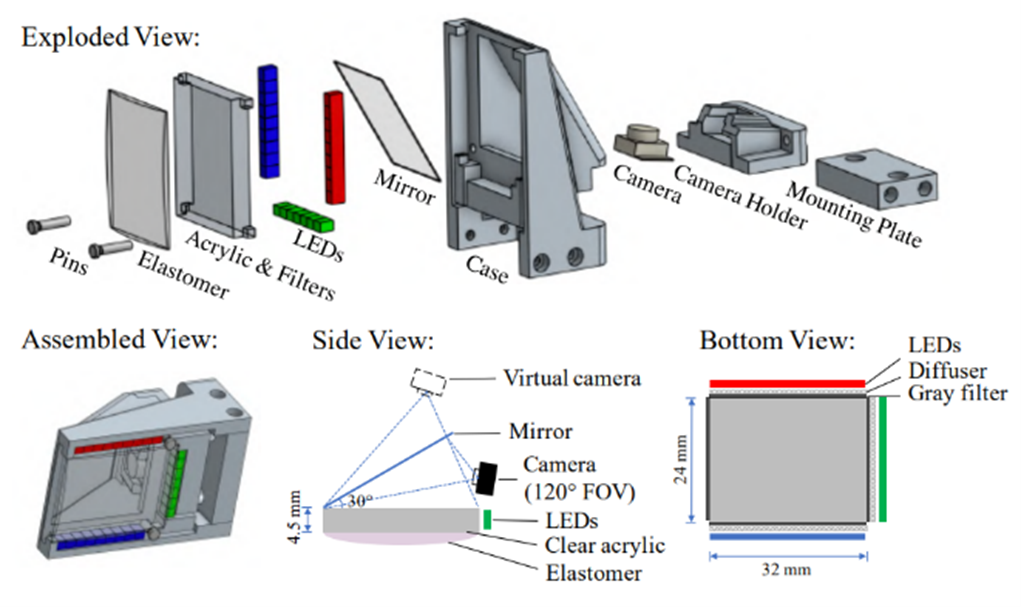

In the past few decades, the development of tactile sensor technology has become the forefront of robotic research that aims to imitate human fingertip sensation. Those tasks, however, are still challenging for robots, as standard force sensors do not obtain enough tactile information at a high enough resolution for them to deduce object shape and mechanical properties. One big development has been a visuotactile sensor called Gelsight, which uses a deformable elastomer contact surface and an embedded camera to capture contact deformations and infer local force/shear. This helps the robot determine the grasped object's physical properties.

The focus of my research was to determine the effectiveness of GelSight sensors within the context of common dynamic locomotion tasks (throwing/catching common objects such as balls, moving carts, performing warehouse tasks). This built on prior research into the mechanical design of GelSight grippers, and their ability to firmly grip objects with a variety of mechanical properties with minimal slip. The aim was to create an optimal mechanical design that maximized sensor resolution and reduced object perception error when detecting common objects in dynamic motion with a bipedal robot.

Results:

From the team I led, I designed a gear-based gripper mechanism that reduced the complexity and number of components of the previous cable-driven mechanism. I also developed an inverse kinematics model to pair with our gain-scheduled controller to ensure the gripper was able to grip objects appropriately. This was all with the ultimate aim to get a better grip and reading on the Gelsight tactile sensors, in which readings were improved by 28%. Through the Research Option at Georgia Tech, I have communicated these ideas in a technical thesis format. From this entire process, I learned a lot about how a formal research study is structured and executed, along with the important communication techniques used to convey findings. This experience ultimately encouraged me to pursue a career in robotics.

Technical Details:

- Our team found that a 3D-printed gripper with one motor and a geared connection between both gripper fingers was the most robust design that adhered to those constraints best. The chosen motor was a Dynamixel XM-430-W350-T motor due to its high-performance control.

- The Lucas-Kanade method provided by the gsrobotics library was utilized to track gel marker positions using the Raspberry Pi mini camera. This optical flow method estimates the displacement of markers on the Gelsight sensor by examining the changes in pixel intensity from the known intensity gradients of the image in that neighborhood. The displacement of markers was directly correlated with the force applied to the sensor by applying a best fit curve to a neo-Hookean curve.

- The gripper's weight being 326g implied it met the specification of being less than 1kg by a factor of safety of 2.32. Furthermore, after approximately 200 gripper attempts, there were no visible signs of stress or fatigue on any component of the system. In comparison, with the cable-driven mechanism, on average there was at least one gripping failure occurring every 12 gripper cycles, often from the cable getting stuck in grooves in the gripper.

- To test the robustness of the gripping mechanism against slip, a gradually increasing mass of solid non-deformable block was used, with the shear forces and shear displacements (based on average marker displacement) measured.

Undergraduate Thesis: